Heat Transfer

HEAT EXCHANGERS

Rev. 0

Page 35

HT-02

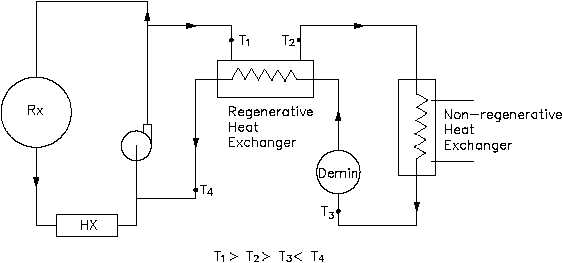

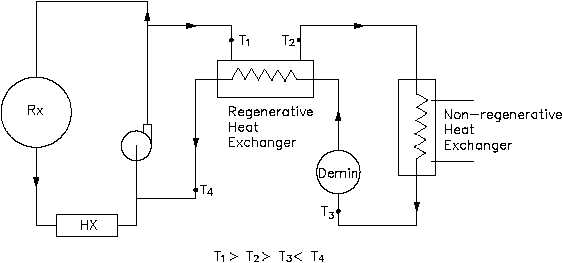

Figure 12 Regenerative Heat Exchanger

The second is to reduce the temperature of the water entering the purification system prior to

reaching the non-regenerative heat exchanger, allowing use of a smaller heat exchanger to

achieve the desired temperature for purification. The primary advantage of a regenerative heat

exchanger application is conservation of system energy (that is, less loss of system energy due

to the cooling of the fluid).

Cooling Towers

The typical function of a cooling tower is to cool the water of a steam power plant by air that

is brought into direct contact with the water. The water is mixed with vapor that diffuses from

the condensate into the air. The formation of the vapor requires a considerable removal of

internal energy from the water; the internal energy becomes "latent heat" of the vapor. Heat and

mass exchange are coupled in this process, which is a steady-state process like the heat exchange

in the ordinary heat exchanger.

Wooden cooling towers are sometimes employed in nuclear facilities and in factories of various

industries. They generally consists of large chambers loosely filled with trays or similar wooden

elements of construction. The water to be cooled is pumped to the top of the tower where it is

distributed by spray or wooden troughs. It then falls through the tower, splashing down from

deck to deck. A part of it evaporates into the air that passes through the tower. The enthalpy

needed for the evaporation is taken from the water and transferred to the air, which is heated

while the water cools. The air flow is either horizontal due to wind currents (cross flow) or

vertically upward in counter-flow to the falling water. The counter-flow is caused by the