Process Controls

VALVE ACTUATORS

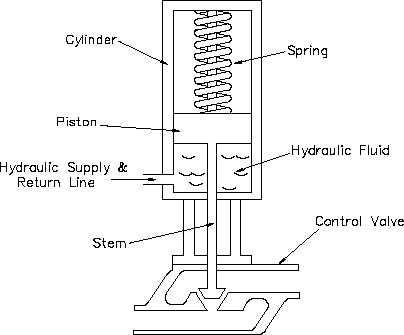

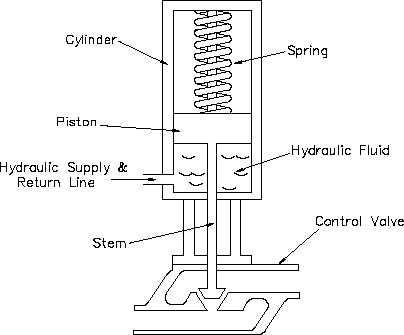

Hydraulic Actuators

Pneumatic actuators are normally used to control processes requiring quick and accurate response,

as they do not require a large amount of motive force. However, when a large amount of force

is required to operate a valve (for example, the main steam system valves), hydraulic actuators

are normally used. Although hydraulic actuators come in many designs, piston types are most

common.

A

typical

piston-type

Figure 37 Hydraulic Actuator

hydraulic actuator is shown

in Figure 37. It consists of

a cylinder, piston, spring,

hydraulic supply and return

line, and stem. The piston

slides vertically inside the

cylinder and separates the

c y l i n d e r

i n t o

t w o

chambers.

The upper

chamber

contains

the

spring

and

the

lower

chamber contains hydraulic

oil.

The hydraulic supply and

return line is connected to

the lower chamber and

allows hydraulic fluid to

flow to and from the lower

chamber of the actuator.

The stem transmits the

motion of the piston to a

valve.

Initially, with no hydraulic fluid pressure, the spring force holds the valve in the closed position.

As fluid enters the lower chamber, pressure in the chamber increases. This pressure results in

a force on the bottom of the piston opposite to the force caused by the spring. When the

hydraulic force is greater than the spring force, the piston begins to move upward, the spring

compresses, and the valve begins to open. As the hydraulic pressure increases, the valve

continues to open. Conversely, as hydraulic oil is drained from the cylinder, the hydraulic force

becomes less than the spring force, the piston moves downward, and the valve closes. By

regulating amount of oil supplied or drained from the actuator, the valve can be positioned

between fully open and fully closed.

Rev. 0

Page 57

IC-07