SPECIALIZED CORROSION

DOE-HDBK-1015/1-93

Corrosion

CH-02

Rev. 0

Page 34

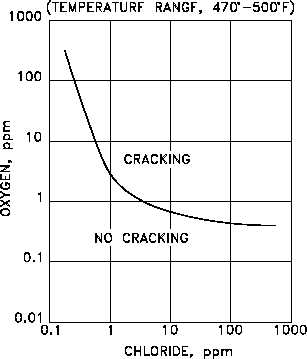

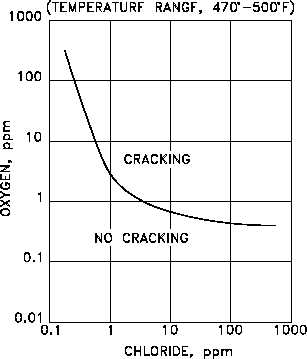

Figure 15 Austenitic Stainless Steel

Caustic Stress Corrosion Cracking

Caustic stress corrosion, or caustic embrittlement, is another form of intergranular

corrosion cracking. The mechanism is similar to that of chloride stress corrosion. Mild

steels (steels with low carbon and low alloy content) and stainless steels will crack if they

are exposed to concentrated caustic (high pH) environments with the metal under a

tensile stress. In stress cracking that is induced by a caustic environment, the presence

of dissolved oxygen is not necessary for the cracking to occur.

Caustic stress corrosion cracking was first encountered in the operation of riveted steam

boilers. These boilers were found to fail on occasion along riveted seams. Failure was

attributed to caustic-induced cracking at the highly stressed regions near and under the

rivets. Boiler water could easily flow into the crevices which existed under the rivets.

Radiative heating would cause the water in the crevices to boil. As steam was formed,

it would escape from the crevice. More boiler water would then flow into the crevice,

boil, and pass from the crevice as steam. The net result of this continuing process was

concentration of caustic under the rivet. The combination of high stress and high caustic

concentrations eventually led to destructive cracking of the boiler vessel.