Diesel Engine Fundamentals

DOE-HDBK-1018/1-93

DIESEL ENGINES

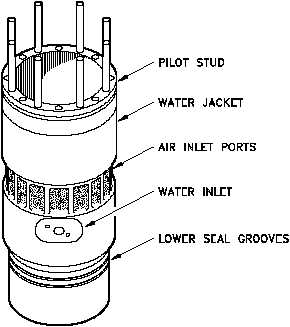

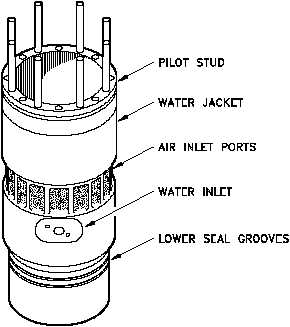

In engines using sleeves, there are two

Figure 5 Diesel Engine Wet Cylinder Sleeve

types of sleeves, wet and dry. A dry

sleeve is surrounded by the metal of

the block and does not come in direct

contact with the engine's coolant

(water). A wet sleeve comes in direct

contact with the engine's coolant.

Figure 5 provides an example of a wet

sleeve. The volume enclosed by the

sleeve or bore is called the combustion

chamber and is the space where the

fuel is burned.

In either type of cylinder, sleeved or

bored, the diameter of the cylinder is

called the bore of the engine and is

stated in inches. For example, the

bore of a 350 cubic inch Chevrolet

gasoline engine is 4 inches.

Most diesel engines are multi-cylinder

engines and typically have their

cylinders arranged in one of two

ways, an in-line or a "V", although other combinations exits. In an in-line engine, as the

name indicates, all the cylinders are in a row. In a "V" type engine the cylinders are

arranged in two rows of cylinders set at an angle to each other that align to a common

crankshaft. Each group of cylinders making up one side of the "V" is referred to as a

bank of cylinders.

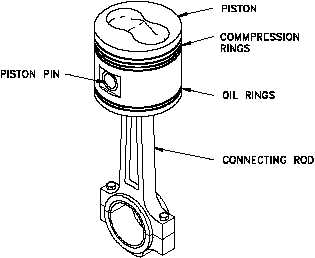

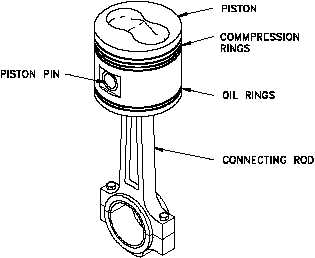

Figure 6 Piston and Piston Rod

Piston and Piston Rings

The piston transforms the energy of

the

expanding

gasses

into

mechanical energy. The piston rides

in the cylinder liner or sleeve as

shown in Figure 2 and Figure 3.

Pistons are commonly made of

aluminum or cast iron alloys.

To prevent the combustion gasses

from bypassing the piston and to

keep friction to a minimum, each

piston has several metal rings around

it, as illustrated by Figure 6.

Rev. 0

ME-01

Page 7