TYPES OF VALVES

DOE-HDBK-1018/2-93

Valves

Butterfly check valves may be

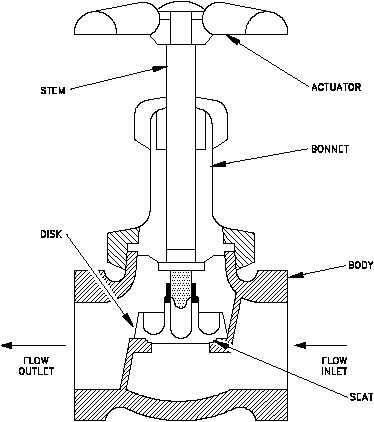

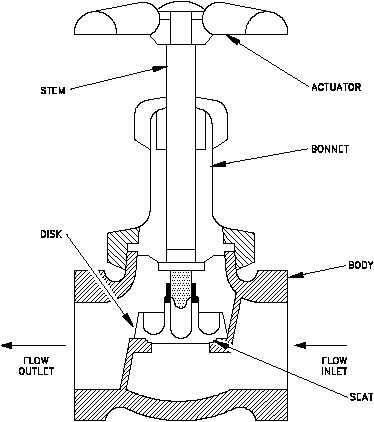

Figure 27 Stop Check Valve

installed

horizontally

or

vertically with the vertical flow

either upward or downward.

Care should be taken to ensure

that the valve is installed so

that the entering flow comes

from the hinge post end of the

valve; otherwise, all flow will

be stopped.

Stop Check Valves

A stop check valve, illustrated

in Figure 27, is a combination

of a lift check valve and a

globe valve.

It has a stem

which, when closed, prevents

the disk from coming off the

seat and provides a tight seal

(similar to a globe valve).

When the stem is operated to

the open position, the valve

operates as a lift check. The

stem is not connected to the

disk and functions to close the

valve tightly or to limit the

travel of the valve disk in the

open direction.

Relief and Safety Valves

Relief and safety valves prevent equipment damage by relieving accidental over-pressurization

of fluid systems. The main difference between a relief valve and a safety valve is the extent of

opening at the setpoint pressure.

A relief valve, illustrated in Figure 28, gradually opens as the inlet pressure increases above the

setpoint. A relief valve opens only as necessary to relieve the over-pressure condition. A safety

valve, illustrated in Figure 29, rapidly pops fully open as soon as the pressure setting is reached.

A safety valve will stay fully open until the pressure drops below a reset pressure. The reset

pressure is lower than the actuating pressure setpoint. The difference between the actuating

pressure setpoint and the pressure at which the safety valve resets is called blowdown.

Blowdown is expressed as a percentage of the actuating pressure setpoint.

ME-04

Rev.0

Page 40