Properties of Metals

DOE-HDBK-1017/1-93

STRAIN

When metal experiences strain, its volume remains constant. Therefore, if volume remains

constant as the dimension changes on one axis, then the dimensions of at least one other axis

must change also. If one dimension increases, another must decrease. There are a few

exceptions. For example, strain hardening involves the absorption of strain energy in the

material structure, which results in an increase in one dimension without an offsetting decrease

in other dimensions. This causes the density of the material to decrease and the volume to

increase.

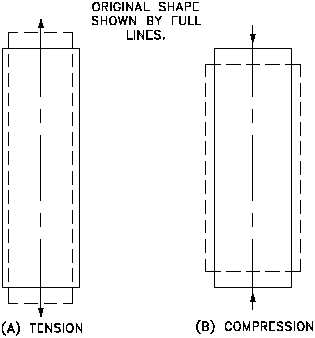

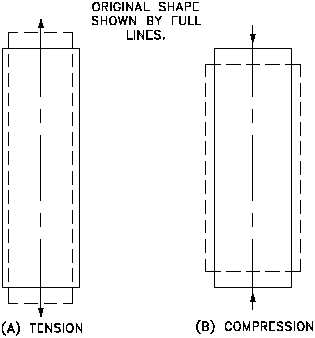

If a tensile load is applied to a material, the material will elongate on the axis of the load

(perpendicular to the tensile stress plane), as illustrated in Figure 2(a). Conversely, if the load

is compressive, the axial dimension will decrease, as illustrated in Figure 2(b). If volume is

constant, a corresponding lateral contraction or expansion must occur. This lateral change will

bear a fixed relationship to the axial strain. The relationship, or ratio, of lateral to axial strain

is called Poisson's ratio after the name of its discoverer. It is usually symbolized by n.

Whether or not a material can deform

Figure 2 Change of Shape of Cylinder Under Stress

plastically at low applied stresses depends

on its lattice structure. It is easier for

planes of atoms to slide by each other if

those

planes

are

closely

packed.

Therefore lattice structures with closely

packed planes

allow more plastic

deformation than those that are not closely

packed.

Also, cubic lattice structures

allow slippage to occur more easily than

non-cubic lattices. This is because of

their symmetry which provides closely

packed planes in several directions. Most

metals are made of the body-centered

cubic (BCC), face-centered cubic (FCC),

or hexagonal close-packed (HCP) crystals,

discussed in more detail in the Module 1,

Structure of Metals.

A face-centered

cubic crystal structure will deform more

readily under load before breaking than a

body-centered cubic structure.

The BCC lattice, although cubic, is not

closely packed and forms strong metals. a-iron and tungsten have the BCC form. The FCC

lattice is both cubic and closely packed and forms more ductile materials. g-iron, silver, gold, and

lead are FCC structured. Finally, HCP lattices are closely packed, but not cubic. HCP metals

like cobalt and zinc are not as ductile as the FCC metals.

Rev. 0

Page 9

MS-02