IMPERFECTIONS IN METALS

DOE-HDBK-1017/1-93

Structure of Metals

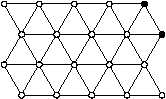

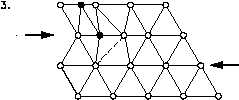

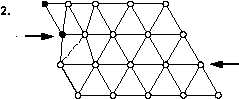

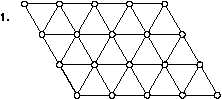

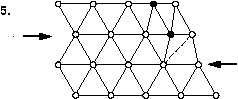

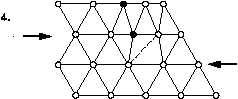

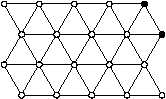

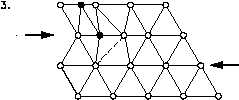

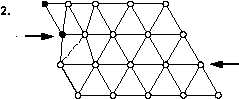

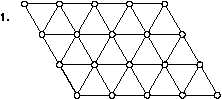

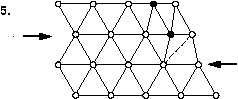

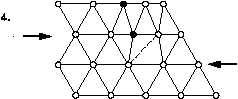

The slip occurs when the crystal is subjected to a stress, and the dislocation moves

through the crystal until it reaches the edge or is arrested by another dislocation, as

shown in Figure 9. Position 1 shows a normal crystal structure. Position 2 shows a force

applied from the left side and a counterforce applied from the right side. Positions 3 to

5 show how the structure is slipping. Position 6 shows the final deformed crystal

structure. The slip of one active plane is ordinarily on the order of 1000 atomic

distances and, to produce yielding, slip on many planes is required.

Screw dislocations can be produced by a tearing of the crystal parallel to the slip

Figure 9 Slips

direction. If a screw dislocation is followed all the way around a complete circuit, it

would show a slip pattern similar to that of a screw thread. The pattern may be either

left or right handed. This requires that some of the atomic bonds are re-formed

continuously so that the crystal has almost the same form after yielding that it had

before.

The orientation of dislocations may vary from pure edge to pure screw. At some

intermediate point, they may possess both edge and screw characteristics.

The

importance of dislocations is based on the ease at which they can move through crystals.

MS-01

Page 20

Rev. 0