Flow Detectors

HEAD FLOW METERS

Orifice Plate

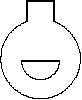

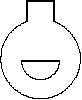

Figure 2 Orifice Plates

The orifice plate is the simplest of

the flowpath restrictions used in

flow detection, as well as the most

economical. Orifice plates are flat

plates 1/16 to 1/4 inch thick.

They

are

normally

mounted

between a pair of flanges and are

installed in a straight run of

smooth pipe to avoid disturbance

of flow patterns from fittings and

valves.

Three kinds of orifice plates are used: concentric, eccentric, and segmental (as shown in Figure

2).

The concentric orifice plate is the most common of the three types. As shown, the orifice is

equidistant (concentric) to the inside diameter of the pipe. Flow through a sharp-edged orifice

plate is characterized by a change in velocity. As the fluid passes through the orifice, the fluid

converges, and the velocity of the fluid increases to a maximum value. At this point, the

pressure is at a minimum value. As the fluid diverges to fill the entire pipe area, the velocity

decreases back to the original value. The pressure increases to about 60% to 80% of the original

input value. The pressure loss is irrecoverable; therefore, the output pressure will always be less

than the input pressure. The pressures on both sides of the orifice are measured, resulting in a

differential pressure which is proportional to the flow rate.

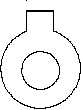

Segmental and eccentric orifice plates are functionally identical to the concentric orifice. The

circular section of the segmental orifice is concentric with the pipe. The segmental portion of

the orifice eliminates damming of foreign materials on the upstream side of the orifice when

mounted in a horizontal pipe. Depending on the type of fluid, the segmental section is placed

on either the top or bottom of the horizontal pipe to increase the accuracy of the measurement.

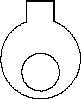

Eccentric orifice plates shift the edge of the orifice to the inside of the pipe wall. This design

also prevents upstream damming and is used in the same way as the segmental orifice plate.

Orifice plates have two distinct disadvantages; they cause a high permanent pressure drop (outlet

pressure will be 60% to 80% of inlet pressure), and they are subject to erosion, which will

eventually cause inaccuracies in the measured differential pressure.

Rev. 0

Page 3

IC-04