Properties of Metals

DOE-HDBK-1017/1-93

PHYSICAL PROPERTIES

The reduction of area is reported as additional information (to the percent elongation) on the

deformational characteristics of the material. The two are used as indicators of ductility, the

ability of a material to be elongated in tension. Because the elongation is not uniform over the

entire gage length and is greatest at the center of the neck, the percent elongation is not an

absolute measure of ductility. (Because of this, the gage length must always be stated when the

percent elongation is reported.) The reduction of area, being measured at the minimum diameter

of the neck, is a better indicator of ductility.

Ductility is more commonly defined as the ability of a material to deform easily upon the

application of a tensile force, or as the ability of a material to withstand plastic deformation

without rupture. Ductility may also be thought of in terms of bendability and crushability.

Ductile materials show large deformation before fracture. The lack of ductility is often termed

brittleness. Usually, if two materials have the same strength and hardness, the one that has the

higher ductility is more desirable. The ductility of many metals can change if conditions are

altered. An increase in temperature will increase ductility. A decrease in temperature will cause

a decrease in ductility and a change from ductile to brittle behavior. Irradiation will also decrease

ductility, as discussed in Module 5.

Cold-working also tends to make metals less ductile. Cold-working is performed in a temperature

region and over a time interval to obtain plastic deformation, but not relieving the strain

hardening. Minor additions of impurities to metals, either deliberate or unintentional, can have

a marked effect on the change from ductile to brittle behavior. The heating of a cold-worked

metal to or above the temperature at which metal atoms return to their equilibrium positions will

increase the ductility of that metal. This process is called annealing.

Ductility is desirable in the high temperature and

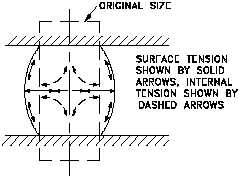

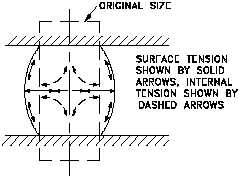

Figure 7 Malleable Deformation of a Cylinder

Under Uniform Axial Compression

high pressure applications in reactor plants because

of the added stresses on the metals. High ductility

in these applications helps prevent brittle fracture,

which is discussed in Module 4.

Where ductility is the ability of a material to

deform easily upon the application of a tensile

force, malleability is the ability of a metal to

exhibit large deformation or plastic response when

being subjected to compressive force. Uniform

compressive force causes deformation in the

manner shown in Figure 7. The material contracts

axially with the force and expands laterally. Restraint due to friction at the contact faces induces

axial tension on the outside. Tensile forces operate around the circumference with the lateral

expansion or increasing girth. Plastic flow at the center of the material also induces tension.

Rev. 0

Page 25

MS-02