Plant Materials

DOE-HDBK-1017/2-93

PLANT MATERIAL PROBLEMS

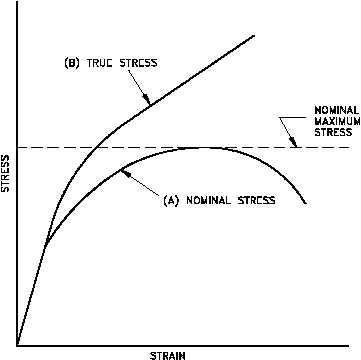

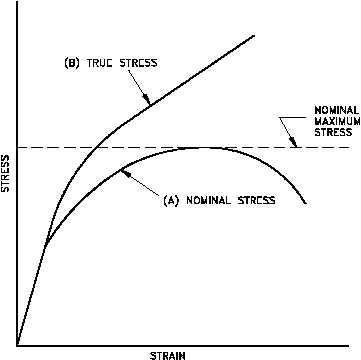

Figure 1 Nominal Stress-Strain Curve

vs True Stress-Strain Curve

Work hardening can also be used to treat material. Prior work hardening (cold working) causes

the treated material to have an apparently higher yield stress.

Therefore, the metal is

strengthened.

Creep

At room temperature, structural materials develop the full strain they will exhibit as soon as a

load is applied. This is not necessarily the case at high temperatures (for example, stainless steel

above 1000F or zircaloy above 500F). At elevated temperatures and constant stress or load,

many materials continue to deform at a slow rate. This behavior is called creep. At a constant

stress and temperature, the rate of creep is approximately constant for a long period of time.

After this period of time and after a certain amount of deformation, the rate of creep increases,

and fracture soon follows. This is illustrated in Figure 2.

Initially, primary or transient creep occurs in Stage I. The creep rate, (the slope of the curve)

is high at first, but it soon decreases. This is followed by secondary (or steady-state) creep in

Stage II, when the creep rate is small and the strain increases very slowly with time.

Eventually, in Stage III (tertiary or accelerating creep), the creep rate increases more rapidly and

the strain may become so large that it results in failure.

Rev. 0

Page 29

MS-05