DOE-HDBK-1018/1-93

FUNDAMENTALS OF THE DIESEL CYCLE

Diesel Engine Fundamentals

To convert the chemical energy of the fuel into useful mechanical energy all internal combustion

engines must go through four events: intake, compression, power, and exhaust. How these

events are timed and how they occur differentiates the various types of engines.

All diesel engines fall into one of two categories, two-stroke or four-stroke cycle engines. The

word cycle refers to any operation or series of events that repeats itself. In the case of a four-

stroke cycle engine, the engine requires four strokes of the piston (intake, compression, power,

and exhaust) to complete one full cycle. Therefore, it requires two rotations of the crankshaft,

or 720 of crankshaft rotation (360 x 2) to complete one cycle. In a two-stroke cycle engine

the events (intake, compression, power, and exhaust) occur in only one rotation of the crankshaft,

or 360.

Timing

In the following discussion of the diesel cycle it is important to keep in mind the time

frame in which each of the actions is required to occur. Time is required to move exhaust

gas out of the cylinder and fresh air in to the cylinders, to compress the air, to inject fuel,

and to burn the fuel. If a four-stroke diesel engine is running at a constant 2100

revolutions per minute (rpm), the crankshaft would be rotating at 35 revolutions, or

12,600 degrees, per second. One stroke is completed in about 0.01429 seconds.

The Four-Stoke Cycle

In a four-stroke engine the camshaft is geared so that it rotates at half the speed of the crankshaft

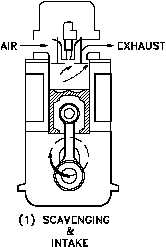

Figure 16 Scavenging and Intake

(1:2). This means that the crankshaft must make two complete revolutions before the camshaft

will complete one revolution. The following section will describe a four-stroke, normally

aspirated, diesel engine having both intake and exhaust valves

with a 3.5-inch bore and 4-inch stroke with a 16:1 compression

ratio, as it passes through one complete cycle. We will start on

the intake stroke. All the timing marks given are generic and

will vary from engine to engine. Refer to Figures 10, 16, and 17

during the following discussion.

Intake

As the piston moves upward and approaches 28 before

top dead center (BTDC), as measured by crankshaft

rotation, the camshaft lobe starts to lift the cam follower.

This causes the pushrod to move upward and pivots the

rocker arm on the rocker arm shaft. As the valve lash is

taken up, the rocker arm pushes the intake valve

downward and the valve starts to open. The intake

stroke now starts while the exhaust valve is still open.

The flow of the exhaust gasses will have created a low

ME-01

Rev. 0

Page 22