FILTERS AND STRAINERS

DOE-HDBK-1018/2-93

Miscellaneous Mechanical Components

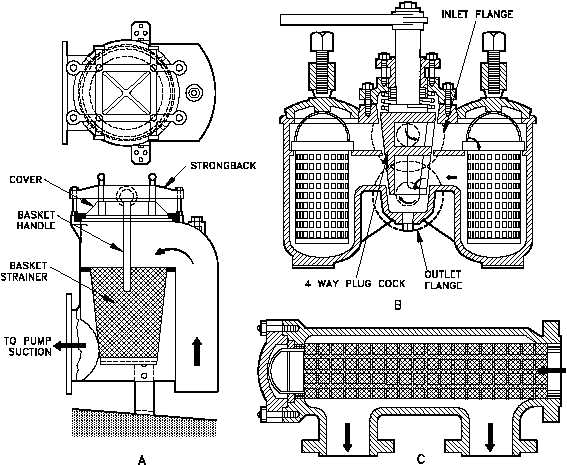

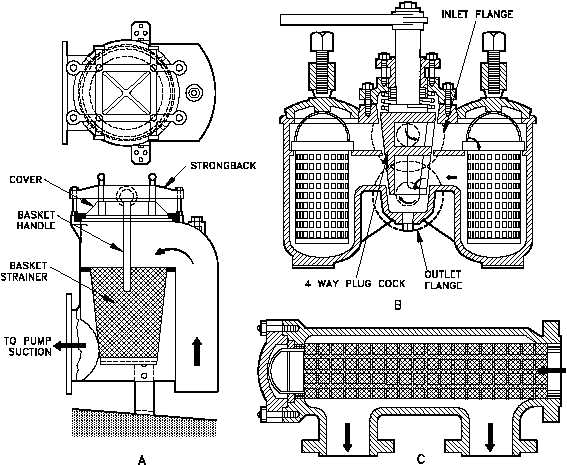

Part C of Figure 24 shows a manifold steam strainer. This type of strainer is desirable where

space is limited, because it eliminates the use of separate strainers and their fittings. The cover

is located so that the strainer basket can be removed for cleaning.

Backwashing

Figure 24 Common Strainers

If the filter or strainer cannot be easily removed for cleaning, the system design will usually

include a flowpath for backwashing. The backwashing of precoated filters has already been

explained because it is more complex than a typical backwash. The intent of a backwash is to

flow liquid in the opposite direction of normal flow, creating a pressure that pushes the debris

off the strainer or filter. The debris is flushed to a waste tank or drain.

Normally, to establish a backwash lineup, the flowpath upstream of the inlet to the strainer or

filter is closed, the flow path downstream of the outlet is closed, and a drain flowpath is opened.

ME-05

Rev. 0

Page 46