Miscellaneous Mechanical Components

DOE-HDBK-1018/2-93

AIR COMPRESSORS

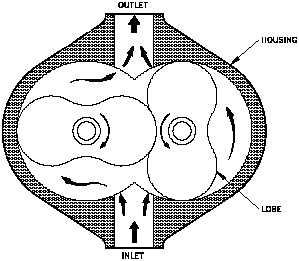

The rotary lobe-type, illustrated in Figure

Figure 4 Rotary Lobe Air Compressor

4, features two mating lobe-type rotors

mounted in a case. The lobes are gear

driven at close clearance, but without

metal-to-metal contact. The suction to the

unit is located where the cavity made by

the lobes is largest. As the lobes rotate,

the cavity size is reduced, causing

compression of the vapor within. The

compression continues until the discharge

port is reached, at which point the vapor

exits the compressor at a higher pressure.

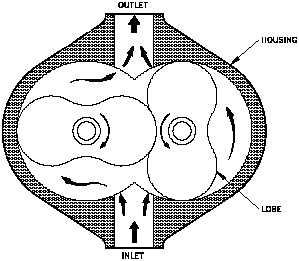

The

rotary

liquid

seal

ring-type,

illustrated in Figure 5, features a forward

inclined, open impeller, in an oblong

cavity filled with liquid. As the impeller

rotates, the centrifugal force causes the

seal liquid to collect at the outer edge of

the oblong cavity. Due to the oblong configuration of the compressor case, large longitudinal

cells are created and reduced to smaller ones. The suction port is positioned where the

longitudinal cells are the largest, and for the discharge port, where they are smallest, thus

causing the vapor within the cell to compress as the rotor rotates. The rotary liquid seal

compressor is frequently used in specialized applications for the compression of extremely

corrosive and exothermic gasses and is commonly used in commercial nuclear plants as a means

of establishing initial condenser vacuum.

Figure 5 Rotary Liquid Seal Ring Air Compressor

Rev. 0

ME-05

Page 5