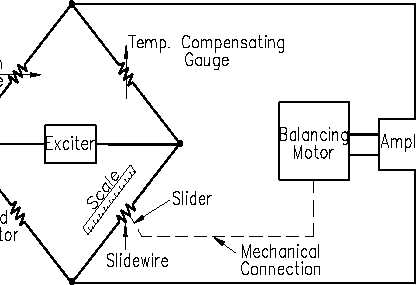

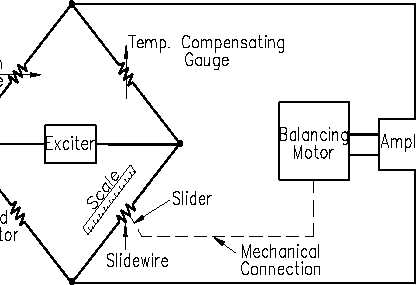

PRESSURE DETECTION CIRCUITRY

Pressure Detectors

An increase in pressure at the inlet of the bellows causes the bellows to expand. The expansion

of the bellows moves a flexible beam to which a strain gauge has been attached. The movement

of the beam causes the resistance of the strain gauge to change. The temperature compensating

gauge compensates for the heat produced by current flowing through the fine wire of the strain

gauge. Strain gauges, which are nothing more than resistors, are used with bridge circuits as

shown in Figure 5.

Figure 5 Strain Gauge Used in a Bridge Circuit

Alternating current is provided by an exciter that is used in place of a battery to eliminate the

need for a galvanometer. When a change in resistance in the strain gauge causes an unbalanced

condition, an error signal enters the amplifier and actuates the balancing motor. The balancing

motor moves the slider along the slidewire, restoring the bridge to a balanced condition. The

slider’s position is noted on a scale marked in units of pressure.

IC-02

Page 8

Rev. 0