DOE-HDBK-1016/1-93

Engineering Fluid Diagrams and Prints

ENGINEERING FLUIDS DIAGRAMS AND PRINTS

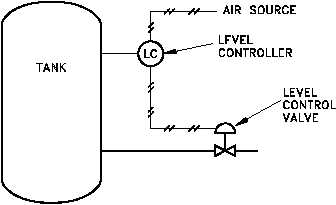

Note that the symbols alone in Figure 3 do not provide the reader with enough information to

determine whether applying air pressure to the diaphragm opens or closes the process control

valve, or whether energizing the solenoid pressurizes or vents the diaphragm. Further, Figure 3

is incomplete in that it does not show the electrical portion of the valve control system nor does

it identify the source of the motive force (compressed air). Although Figure 3 informs the reader

of the types of mechanical components in the control system and how they interconnect, it does

not provide enough information to determine how those components react to a control signal.

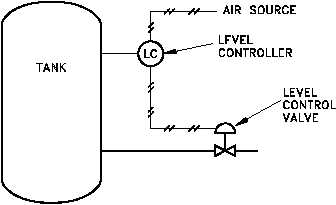

Control valves operated by an instrument signal are symbolized in the same manner as those

shown previously, except the output of the controlling instrument goes to the valve actuator.

Figure 4 shows a level instrument (designated "LC") that controls the level in the tank by

positioning an air-operated diaphragm control valve. Again, note that Figure 4 does not contain

enough information to enable the reader to determine how the control valve responds to a change

in level.

Figure 4 Level Control Valve

An additional aspect of some control valves is a valve positioner, which allows more precise

control of the valve. This is especially useful when instrument signals are used to control the

valve. An example of a valve positioner is a set of limit switches operated by the motion of the

valve. A positioner is symbolized by a square box on the stem of the control valve actuator. The

positioner may have lines attached for motive force, instrument signals, or both. Figure 5 shows

two examples of valves equipped with positioners. Note that, although these examples are more

detailed than those of Figure 3 and Figure 4, the reader still does not have sufficient information

to fully determine response of the control valve to a change in control signal.

Rev. 0

PR-02

Page 5