DOE-HDBK-1016/1-93

ENGINEERING FLUIDS DIAGRAMS AND PRINTS

Engineering Fluid Diagrams and Prints

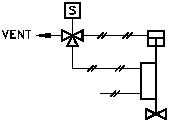

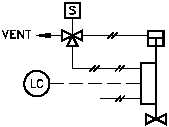

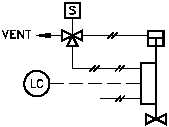

Figure 5 Control Valves with Valve Positioners

In Example A of Figure 5, the reader can reasonably assume that opening of the control valve

is in some way proportional to the level it controls and that the solenoid valve provides an

override of the automatic control signals. However, the reader cannot ascertain whether it opens

or closes the control valve. Also, the reader cannot determine in which direction the valve moves

in response to a change in the control parameter. In Example B of Figure 5, the reader can make

the same general assumptions as in Example A, except the control signal is unknown. Without

additional information, the reader can only assume the air supply provides both the control signal

and motive force for positioning the control valve. Even when valves are equipped with

positioners, the positioner symbol may appear only on detailed system diagrams. Larger, overall

system diagrams usually do not show this much detail and may only show the examples of

Figure 5 as air-operated valves with no special features.

Control Valve Designations

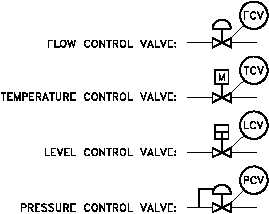

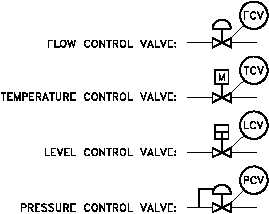

Figure 6 Control Valve Designations

A control valve may serve any number of functions within a fluid system. To differentiate

between valve uses, a balloon labeling system is used to identify the function of a control valve,

as shown in Figure 6. The common convention

is that the first letter used in the valve designator

indicates the parameter to be controlled by the

valve. For example:

F = flow

T = temperature

L = level

P = pressure

H = hand (manually operated valve)

The second letter is usually a "C" and identifies

the valve as a controller, or active component, as

opposed to a hand-operated valve. The third

letter is a "V" to indicate that the piece of

equipment is a valve.

PR-02

Rev. 0

Page 6