Properties of Metals

DOE-HDBK-1017/1-93

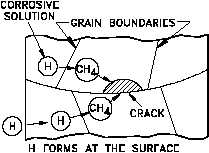

HYDROGEN EMBRITTLEMENT

If the metal is under a high tensile stress, brittle

Figure 10 Hydrogen Embrittlement

failure can occur. At normal room temperatures, the

hydrogen atoms are absorbed into the metal lattice

and diffused through the grains, tending to gather at

inclusions or other lattice defects. If stress induces

cracking under these conditions, the path is

transgranular. At high temperatures, the absorbed

hydrogen tends to gather in the grain boundaries and

stress-induced cracking is then intergranular. The

cracking of martensitic and precipitation hardened

steel alloys is believed to be a form of hydrogen

stress corrosion cracking that results from the entry

into the metal of a portion of the atomic hydrogen that is produced in the following corrosion

reaction.

3 Fe + 4 H2O Fe3O4 + 4 H2

Hydrogen embrittlement is not a permanent condition. If cracking does not occur and the

environmental conditions are changed so that no hydrogen is generated on the surface of the

metal, the hydrogen can rediffuse from the steel, so that ductility is restored.

To address the problem of hydrogen embrittlement, emphasis is placed on controlling the amount

of residual hydrogen in steel, controlling the amount of hydrogen pickup in processing,

developing alloys with improved resistance to hydrogen embrittlement, developing low or no

embrittlement plating or coating processes, and restricting the amount of in-situ (in position)

hydrogen introduced during the service life of a part.

Hydrogen embrittlement is a problem with zirconium and zirconium alloys, which often are used

as cladding materials for nuclear reactors. Zirconium reacts with water as follows.

Zr + 2 H2O ZrO2 + 2H2

Part of the hydrogen produced by the corrosion of zirconium in water combines with the

zirconium to form a separate phase of zirconium hydride (ZrH1.5) platelets. The metal then

becomes embrittled (ductility decreases) and it fractures easily. Cracks begin to form in the

zirconium hydride platelets and are propagated through the metal. Zircaloy-2 (a zirconium alloy),

which has been used as a fuel rod cladding, may absorb as much as 50% of the corrosion-

produced hydrogen and is subject to hydrogen embrittlement, especially in the vicinity of the

surface. Studies at Westinghouse, Batelle, and elsewhere have revealed that the nickel in the

zircaloy-2 was responsible for the hydrogen pickup. This has led to the development of zircaloy-

4, which has significantly less nickel than zircaloy-2 and is less susceptible to embrittlement. In

addition, the introduction of niobium into zircaloy-4 further reduces the amount of hydrogen

absorption.

MS-02

Page 38

Rev. 0