PLANT MATERIAL PROBLEMS

DOE-HDBK-1017/2-93

Plant Materials

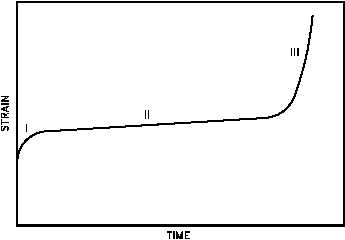

Figure 2 Successive Stages of Creep with Increasing Time

The rate of creep is highly dependent on both stress and temperature. With most of the

engineering alloys used in construction at room temperature or lower, creep strain is so small

at working loads that it can safely be ignored. It does not become significant until the stress

intensity is approaching the fracture failure strength. However, as temperature rises creep

becomes progressively more important and eventually supersedes fatigue as the likely criterion

for failure. The temperature at which creep becomes important will vary with the material.

For safe operation, the total deformation due to creep must be well below the strain at which

failure occurs. This can be done by staying well below the creep limit, which is defined as the

stress to which a material can be subjected without the creep exceeding a specified amount after

a given time at the operating temperature (for example, a creep rate of 0.01 in 100,000 hours

at operating temperature). At the temperature at which high-pressure vessels and piping operate,

the creep limit generally does not pose a limitation. On the other hand, it may be a drawback

in connection with fuel element cladding. Zircaloy has a low creep limit, and zircaloy creep is

a major consideration in fuel element design. For example, the zircaloy cladding of fuel

elements in PWRs has suffered partial collapse caused by creep under the influence of high

temperature and a high pressure load. Similarly, creep is a consideration at the temperatures that

stainless-steel cladding encounters in gas-cooled reactors and fast reactors where the stainless-

steel cladding temperature may exceed 540C.

MS-05

Page 30

Rev. 0