Heat Exchangers

DOE-HDBK-1018/1-93

HEAT EXCHANGER APPLICATIONS

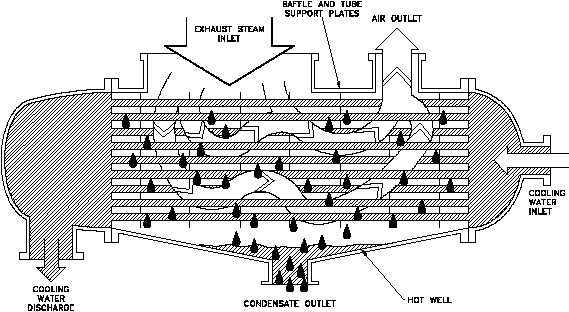

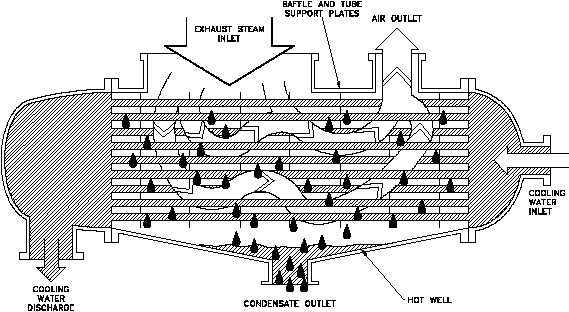

Figure 9 Single-Pass Condenser

There are different condenser designs, but the most common, at least in the large power

generation facilities, is the straight-through, single-pass condenser illustrated Figure 9. This

condenser design provides cooling water flow through straight tubes from the inlet water box

on one end, to the outlet water box on the other end. The cooling water flows once through the

condenser and is termed a single pass. The separation between the water box areas and the

steam condensing area is accomplished by a tube sheet to which the cooling water tubes are

attached. The cooling water tubes are supported within the condenser by the tube support sheets.

Condensers normally have a series of baffles that redirect the steam to minimize direct

impingement on the cooling water tubes. The bottom area of the condenser is the hotwell, as

shown in Figure 9. This is where the condensate collects and the condensate pump takes its

suction. If noncondensable gasses are allowed to build up in the condenser, vacuum will

decrease and the saturation temperature at which the steam will condense increases.

Non-condensable gasses also blanket the tubes of the condenser, thus reducing the heat transfer

surface area of the condenser. This surface area can also be reduced if the condensate level is

allowed to rise over the lower tubes of the condenser. A reduction in the heat transfer surface

has the same effect as a reduction in cooling water flow. If the condenser is operating near its

design capacity, a reduction in the effective surface area results in difficulty maintaining

condenser vacuum.

The temperature and flow rate of the cooling water through the condenser controls the

temperature of the condensate. This in turn controls the saturation pressure (vacuum) of the

condenser.

Rev. 0

ME-02

Page 15