AIR COMPRESSORS

DOE-HDBK-1018/2-93

Miscellaneous Mechanical Components

Centrifugal Compressors

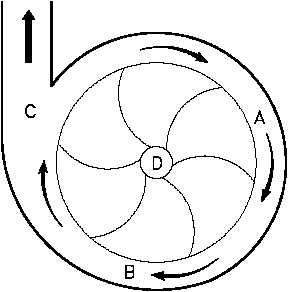

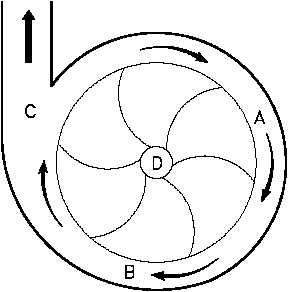

Figure 6 Simplified Centrifugal Pump

The centrifugal compressor, originally

built to handle only large volumes of low

pressure gas and air (maximum of 40

psig), has been developed to enable it to

move large volumes of gas with discharge

pressures up to 3,500 psig. However,

centrifugal compressors are now most

frequently used for medium volume and

medium pressure air delivery.

One

advantage of a centrifugal pump is the

smooth discharge of the compressed air.

The centrifugal force utilized by the

centrifugal compressor is the same force

utilized by the centrifugal pump. The air

particles enter the eye of the impeller,

designated D in Figure 6.

As the

impeller rotates, air is thrown against the

casing of the compressor.

The air

becomes compressed as more and more air is thrown out to the casing by the impeller blades.

The air is pushed along the path designated A, B, and C in Figure 6. The pressure of the air

is increased as it is pushed along this path. Note in Figure 6 that the impeller blades curve

forward, which is opposite to the backward curve used in typical centrifugal liquid pumps.

Centrifugal compressors can use a variety of blade orientation including both forward and

backward curves as well as other designs.

There may be several stages to a centrifugal air compressor, as in the centrifugal pump, and the

result would be the same; a higher pressure would be produced. The air compressor is used to

create compressed or high pressure air for a variety of uses. Some of its uses are pneumatic

control devices, pneumatic sensors, pneumatic valve operators, pneumatic motors, and starting

air for diesel engines.

Compressor Coolers

The amount of moisture that air can hold is inversely proportional to the pressure of the air. As

the pressure of the air increases, the amount of moisture that air can hold decreases. The amount

of moisture that air can hold is also proportional to the temperature of the air. As the

temperature of the air increases, the amount of moisture it can hold increases. However, the

pressure change of compressed air is larger than the temperature change of the compressed air.

This causes the moisture in the air to condense. Moisture in compressed air systems can cause

serious damage. The condensed moisture can cause corrosion, water hammers, and freeze

damage; therefore, it is important to avoid moisture in compressed air systems. Coolers are used

to minimize the problems caused by heat and moisture in compressed air systems.

ME-05

Rev. 0

Page 6