Miscellaneous Mechanical Components

DOE-HDBK-1018/2-93

AIR COMPRESSORS

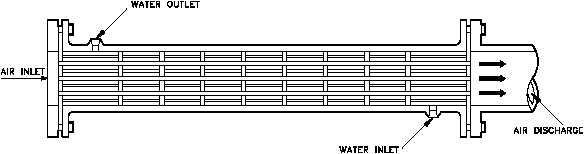

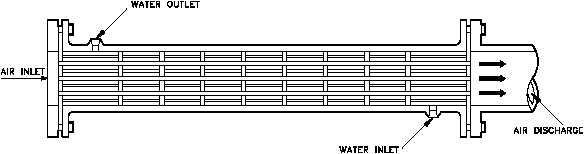

Coolers used on the discharge of a compressor are called aftercoolers. Their purpose is to

remove the heat generated during the compression of the air. The decrease in temperature

promotes the condensing of any moisture present in the compressed air. This moisture is

collected in condensate traps that are either automatically or manually drained.

If the compressor is multi-staged, there may be an intercooler, which is usually located after the

first stage discharge and before the second stage suction. The principle of the intercooler is the

same as that of the aftercoolers. The result is drier, cooler, compressed air. The structure of

a particular cooler depends on the pressure and volume of the air it cools. Figure 7 illustrates

a typical compressor air cooler. Air coolers are used because drier compressed air helps prevent

corrosion and cooler compressed air allows more air to be compressed for a set volume.

Figure 7 Compressor Air Cooler

Hazards of Compressed Air

People often lack respect for the power in compressed air because air is so common and is often

viewed as harmless. At sufficient pressures, compressed air can cause serious damage if handled

incorrectly. To minimize the hazards of working with compressed air, all safety precautions

should be followed closely.

Small leaks or breaks in the compressed air system can cause minute particles to be blown at

extremely high speeds. Always wear safety glasses when working in the vicinity of any

compressed air system. Safety goggles are recommended if contact lenses are worn.

Compressors can make an exceptional amount of noise while running. The noise of the

compressor, in addition to the drain valves lifting, creates enough noise to require hearing

protection. The area around compressors should normally be posted as a hearing protection

zone.

Rev. 0

ME-05

Page 7