Heat Transfer

HEAT GENERATION

However, the rate of increase will vary along with the linear heat flux of the channel. The power

density and linear heat rate will follow the neutron flux shape. However, the temperature

distributions are skewed by the changing capacity of the coolant to remove the heat energy.

Since the coolant increases in temperature as it flows up the channel, the fuel cladding and, thus,

the fuel temperatures are higher in the upper axial region of the core.

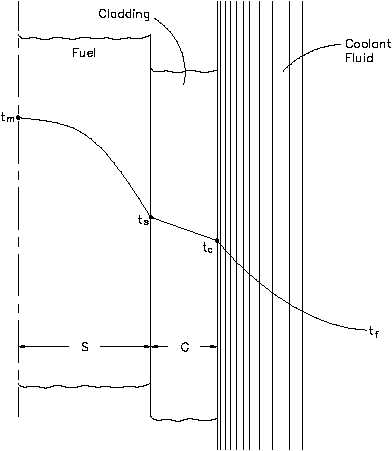

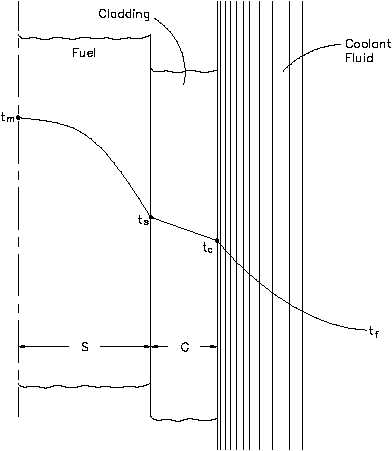

A radial temperature profile across a reactor core (assuming all channel coolant flows are equal)

will basically follow the radial power distribution. The areas with the highest heat generation

rate (power) will produce the most heat and have the highest temperatures. A radial temperature

profile for an individual fuel rod and coolant channel is shown in Figure 17. The basic shape

of the profile will be dependent upon the heat transfer coefficient of the various materials

involved. The temperature differential across each material will have to be sufficient to transfer

the heat produced. Therefore, if we know the heat transfer coefficient for each material and the

heat flux, we can calculate peak fuel temperatures for a given coolant temperature.

Figure 17 Radial Temperature Profile Across a

Fuel Rod and Coolant Channel

Rev. 0

Page 49

HT-02