Process Controls

VALVE ACTUATORS

A major advantage of solenoid actuators is their quick operation. Also, they are much easier to

install than pneumatic or hydraulic actuators.

However, solenoid actuators have two

disadvantages. First, they have only two positions: fully open and fully closed. Second, they

don’t produce much force, so they usually only operate relatively small valves.

Electric Motor Actuators

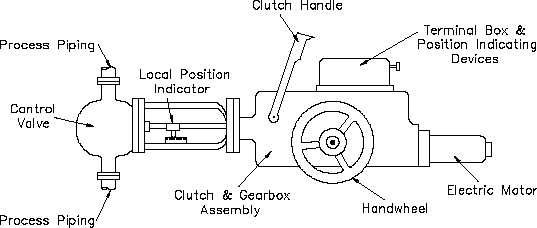

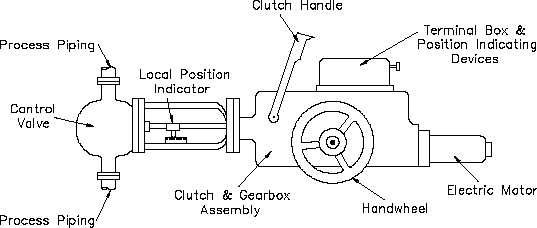

Electric motor actuators vary widely in their design and applications. Some electric motor

actuators are designed to operate in only two positions (fully open or fully closed). Other electric

motors can be positioned between the two positions. A typical electric motor actuator is shown

in Figure 39. Its major parts include an electric motor, clutch and gear box assembly, manual

handwheel, and stem connected to a valve.

Figure 39 Electric Motor Actuator

The motor moves the stem through the gear assembly. The motor reverses its rotation to either

open or close the valve. The clutch and clutch lever disconnects the electric motor from the gear

assembly and allows the valve to be operated manually with the handwheel.

Most electric motor actuators are equipped with limit switches, torque limiters, or both. Limit

switches de-energize the electric motor when the valve has reached a specific position. Torque

Rev. 0

Page 59

IC-07