VALVE ACTUATORS

Process Controls

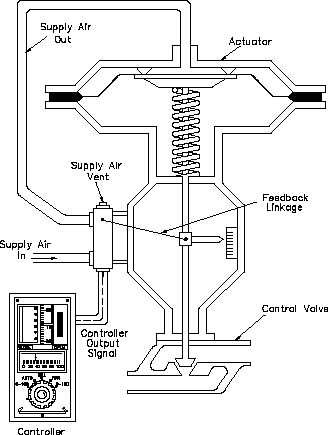

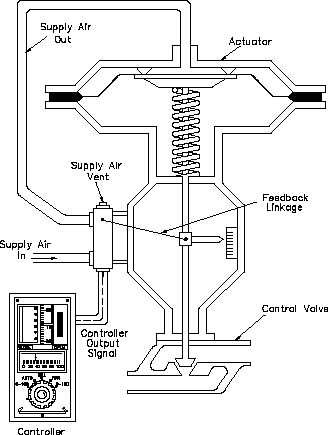

For example, as the control signal increases, a valve inside the positioner admits more supply air

Figure 36 Pneumatic Actuator with Controller and Positioner

to the actuator. As a result, the control valve moves downward. The linkage transmits the valve

position information back to the positioner. This forms a small internal feedback loop for the

actuator. When the valve reaches the position that correlates to the control signal, the linkage

stops supply air flow to the actuator. This causes the actuator to stop. On the other hand, if the

control signal decreases, another valve inside the positioner opens and allows the supply air

pressure to decrease by venting the supply air. This causes the valve to move upward and open.

When the valve has opened to the proper position, the positioner stops venting air from the

actuator and stops movement of the control valve.

An important safety feature is provided by the spring in an actuator. It can be designed to

position a control valve in a safe position if a loss of supply air occurs. On a loss of supply air,

the actuator in Figure 36 will fail open. This type of arrangement is referred to as "air-to-close,

spring-to-open" or simply "fail-open." Some valves fail in the closed position. This type of

actuator is referred to as "air-to-open, spring-to-close" or "fail-closed." This "fail-safe" concept

is an important consideration in nuclear facility design.

IC-07

Page 56

Rev. 0