DOE-HDBK-1016/1-93

Engineering Fluid Diagrams and Prints

ENGINEERING FLUIDS DIAGRAMS AND PRINTS

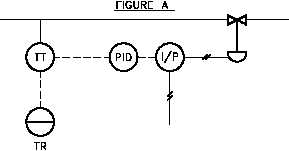

Examples of Simple Instrument Loops

Figure 14 shows two examples of

Figure 14 Instrumentation System Examples

simple instrument loops. Figure 14

(A) shows a temperature transmitter

(TT), which generates two electrical

signals. One signal goes to a board-

mounted temperature recorder (TR) for

display. The second signal is sent to

a proportional-integral-derivative (PID)

controller, the output of which is sent

to a current-to-pneumatic modifier

(I/P). In the I/P modifier, the electric

signal is converted into a pneumatic

signal, commonly 3 psi to 15 psi,

which in turn operates the valve. The

function of the complete loop is to

modify flow based on process fluid

temperature. Note that there is not

enough information to determine how

flow and temperature are related and

what the setpoint is, but in some

instances the setpoint is stated on a

P&ID.

Knowing the setpoint and

purpose of the system will usually be

sufficient to allow the operation of the

instrument loop to be determined.

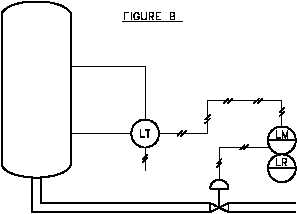

The pneumatic level transmitter (LT) illustrated in Figure 14 (B) senses tank level. The output

of the level transmitter is pneumatic and is routed to a board-mounted level modifier (LM). The

level modifier conditions the signal (possibly boosts or mathematically modifies the signal) and

uses the modified signal for two purposes. The modifier drives a board-mounted recorder (LR)

for indication, and it sends a modified pneumatic signal to the diaphragm-operated level control

valve. Notice that insufficient information exists to determine the relationship between sensed

tank level and valve operation.

Components

Within every fluid system there are major components such as pumps, tanks, heat exchangers,

and fans. Figure 15 shows the engineering symbols for the most common major components.

Rev. 0

PR-02

Page 13