THERMAL STRESS

DOE-HDBK-1017/2-93

Thermal Shock

Thermal stresses are a major concern in

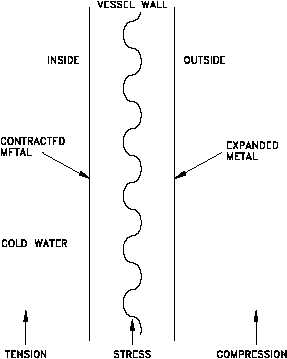

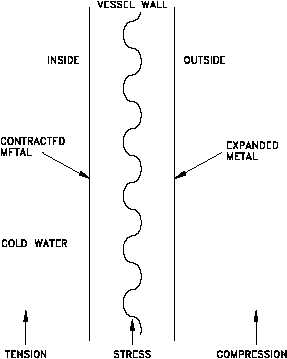

Figure 1 Stress on Reactor Vessel Wall

reactor systems due to the magnitude of the

stresses involved. With rapid heating (or

cooling) of a thick-walled vessel such as

the reactor pressure vessel, one part of the

wall may try to expand (or contract) while

the adjacent section, which has not yet been

exposed to the temperature change, tries to

restrain it. Thus, both sections are under

stress. Figure 1 illustrates what takes place.

A vessel is considered to be thick-walled or

thin-walled based on comparing the

thickness of the vessel wall to the radius of

the vessel. If the thickness of the vessel

wall is less than about 1 percent of the

vessel's radius, it is usually considered a

thin-walled vessel. If the thickness of the

vessel wall is more than 5 percent to 10

percent of the vessel's radius, it is

considered a thick-walled vessel. Whether

a vessel with wall thickness between 1

percent and 5 percent of radius is

considered thin-walled or thick-walled

depends on the exact design, construction,

and application of the vessel.

When cold water enters the vessel, the cold water causes the metal on the inside wall (left side

of Figure 1) to cool before the metal on the outside. When the metal on the inside wall cools,

it contracts, while the hot metal on the outside wall is still expanded. This sets up a thermal

stress, placing the cold side in tensile stress and the hot side in compressive stress, which can

cause cracks in the cold side of the wall. These stresses are illustrated in Figure 2 and Figure 3

in the next chapter.

The heatup and cooldown of the reactor vessel and the addition of makeup water to the reactor

coolant system can cause significant temperature changes and thereby induce sizable thermal

stresses. Slow controlled heating and cooling of the reactor system and controlled makeup

water addition rates are necessary to minimize cyclic thermal stress, thus decreasing the

potential for fatigue failure of reactor system components.

Operating procedures are designed to reduce both the magnitude and the frequency of these

stresses. Operational limitations include heatup and cooldown rate limits for components,

temperature limits for placing systems in operation, and specific temperatures for specific

pressures for system operations. These limitations permit material structures to change

temperature at a more even rate, minimizing thermal stresses.

MS-03

Page 4

Rev. 0