Thernal Shock

DOE-HDBK-1017/2-93

PRESSURIZED THERMAL SHOCK

Stresses arising from coolant system pressure

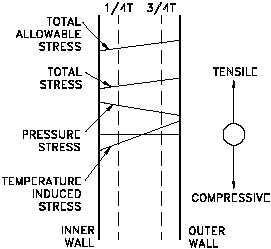

Figure 2 Heatup Stress Profile

exerted against the inside vessel wall (where

neutron fluence is greatest) are always tensile in

nature.

Stresses arising from temperature

gradients across the vessel wall can either be

tensile or compressive. The type of stress is a

function of the wall thickness and reverses from

heatup to cooldown. During system heatup, the

vessel outer wall temperature lags the inner wall

temperature.

The stresses produced by this

temperature gradient and by system pressure will

produce the profile shown in Figure 2.

During heatup, it can be seen that while the

pressure stresses are always tensile, at the 1/4

thickness (1/4 T), the temperature stresses are

compressive. Thus, the stresses at the 1/4 T

location tend to cancel during system heatup. At

the 3/4 T location, however, the stresses from

both temperature and pressure are tensile and thus, reinforce each other during system heatup.

For this reason the 3/4 T location is limiting during system heatup.

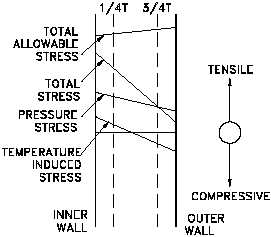

During system cooldown, the stress profile of

Figure 3 Cooldown Stress Profile

Figure 3 is obtained. During cooldown, the outer

wall lags the temperature drop of the inner wall

and is at a higher temperature. It can be seen

that during cooldown, the stresses at the 3/4 T

location are tensile due to system pressure and

compressive due to the temperature gradient.

Thus during cooldown, the stresses at the 3/4 T

location tend to cancel. At the 1/4 T location,

however, the pressure and temperature stresses

are both tensile and reinforce each other. Thus,

the 1/4 T location is limiting during system

cooldown.

Plant temperature transients that have the greatest

potential for causing thermal shock include

excessive plant heatup and cooldown, plant

scrams, plant pressure excursions outside of

normal pressure bands, and loss of coolant

accidents (LOCAs). In pressurized water reactors (PWRs), the two transients that can cause the

most severe thermal shock to the reactor pressure vessel are the LOCA with subsequent injection

of emergency core cooling system (ECCS) water and a severe increase in the primary-to-

secondary heat transfer.

Rev. 0

Page 7

MS-03