EFFECT DUE TO NEUTRON CAPTURE

DOE-HDBK-1017/2-93

Plant Materials

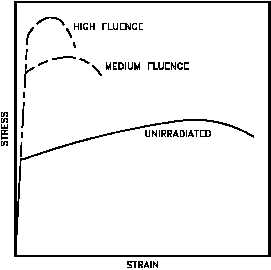

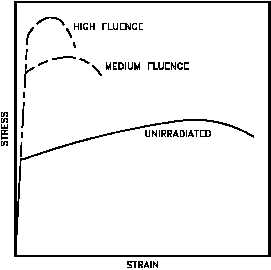

Figure 4 Qualitative Representation of Neutron

Irradiation Effect on Many Metals

For stainless steel exposed to a thermal reactor fluence of 1021 neutrons/cm2, the tensile

properties show some increase in ultimate strength (tensile strength), an almost threefold gain

in the yield strength, and a drop of about one third in ductility (elongation), as shown in

Table 2.

The Nil-Ductility Transition (NDT) temperature, which is the temperature at which a given metal

changes from ductile to brittle fracture, is often markedly increased by neutron irradiation. The

increase in the NDT temperature is one of the most important effects of irradiation from the

standpoint of nuclear power system design. For economic reasons, the large core pressure

vessels of large power reactors have been constructed of low carbon steels.

The loss of ductility and increase in the NDT temperature of these vessels is a primary concern

to reactor designers because of the increased chance of brittle fracture. Brittle fracture of a

material is a failure occurring by crystal cleavage and accompanied by essentially no yielding.

A brittle fracture of a pressure vessel resembles the shattering of glass. Since such a failure

would be disastrous, it is necessary to understand the brittle fracture mechanism. During normal

reactor operation, the pressure-vessel steel is subject to increasing fluence of fast neutrons and,

as a result, the NDT temperature increases steadily. The NDT temperature is not likely to

increase sufficiently to approach the temperature of the steel in the pressure vessel. However,

as the reactor is being cooled down, the temperature of the vessel may drop below the NDT

value while the reactor vessel is still pressurized. Brittle fracture might then occur.

MS-05

Page 40

Rev. 0