TYPES OF VALVES

DOE-HDBK-1018/2-93

Valves

Flow to lift check valves must always enter below the seat. As the flow enters, the disk or ball

is raised within guides from the seat by the pressure of the upward flow. When the flow stops

or reverses, the disk or ball is forced onto the seat of the valve by both the backflow and

gravity.

Some types of lift check valves may be installed horizontally. In this design, the ball is

suspended by a system of guide ribs. This type of check valve design is generally employed in

plastic check valves.

The seats of metallic body lift check valves are either integral with the body or contain

renewable seat rings. Disk construction is similar to the disk construction of globe valves with

either metal or composition disks. Metal disk and seat valves can be reground using the same

techniques as is used for globe valves.

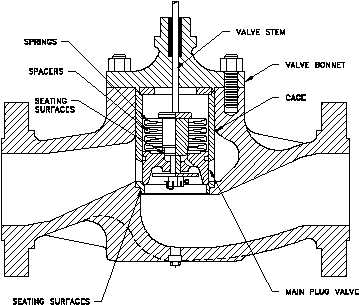

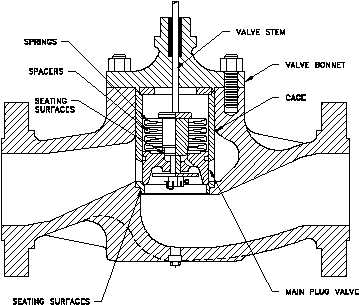

Piston Check Valves

Figure 25 Piston Check Valve

A piston check valve, illustrated in

Figure 25, is essentially a lift

check valve.

It has a dashpot

consisting of a piston and cylinder

that provides a cushioning effect

during operation. Because of the

similarity in design to lift check

valves, the flow characteristics

through a piston check valve are

essentially the same as through a

lift check valve.

Installation is the same as for a lift

check in that the flow must enter

from under the seat. Construction

of the seat and disk of a piston

check valve is the same as for lift

check valves.

Piston check valves are used primarily in conjunction with globe and angle valves in piping

systems experiencing very frequent changes in flow direction. Valves of this type are used on

water, steam, and air systems.

ME-04

Rev.0

Page 38