Valves

DOE-HDBK-1018/2-93

TYPES OF VALVES

Stem seals are accomplished either with packing in a conventional stuffing box or by means of

O-ring seals. Some valve manufacturers, particularly those specializing in the handling of

corrosive materials, place a stem seal on the inside of the valve so that no material being

handled by the valve can come into contact with the valve stem. If a stuffing box or external

O-ring is employed, the fluid passing through the valve will come into contact with the valve

stem.

Needle Valves

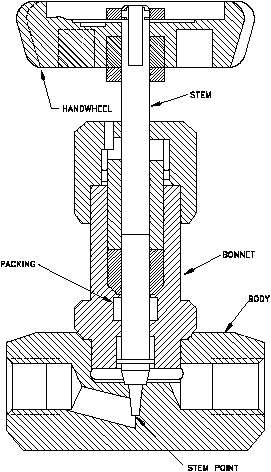

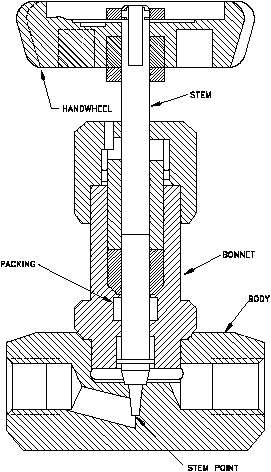

Figure 20 Needle Valve

A needle valve, as shown in Figure 20, is

used to make relatively fine adjustments

in the amount of fluid flow.

The distinguishing characteristic of a

needle valve is the long, tapered, needle-

like point on the end of the valve stem.

This "needle" acts as a disk. The longer

part of the needle is smaller than the

orifice in the valve seat and passes

through the orifice before the needle

seats. This arrangement permits a very

gradual increase or decrease in the size of

the opening.

Needle valves are often

used as component parts of other, more

complicated valves. For example, they

are used in some types of reducing

valves.

Needle Valve Applications

Most constant pressure pump governors

have needle valves to minimize the effects

of fluctuations in pump discharge

pressure. Needle valves are also used in

some

components

of

automatic

combustion control systems where very

precise flow regulation is necessary.

Rev. 0

ME-04

Page 33