Valves

DOE-HDBK-1018/2-93

TYPES OF VALVES

Pinch Valve Bodies

Pinch valves have molded bodies reinforced with fabric. Pinch valves generally have a

maximum operating temperature of 250oF. At 250oF, maximum operating pressure varies

generally from 100 psig for a 1-inch diameter valve and decreases to 15 psig for a 12-inch

diameter valve. Special pinch valves are available for temperature ranges of -100oF to 550oF

and operating pressures of 300 psig.

Most pinch valves are supplied with the sleeve (valve body) exposed. Another style fully

encloses the sleeve within a metallic body. This type controls flow either with the conventional

wheel and screw pinching device, hydraulically, or pneumatically with the pressure of the liquid

or gas within the metal case forcing the sleeve walls together to shut off flow.

Most exposed sleeve valves have limited vacuum application because of the tendency of the

sleeves to collapse when vacuum is applied. Some of the encased valves can be used on vacuum

service by applying a vacuum within the metal casing and thus preventing the collapse of the

sleeve.

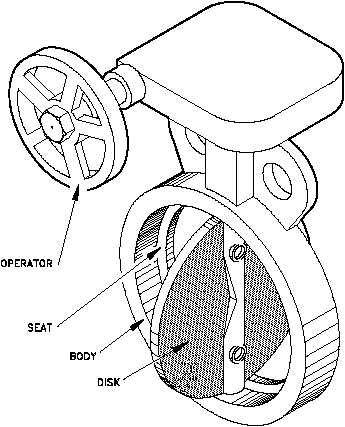

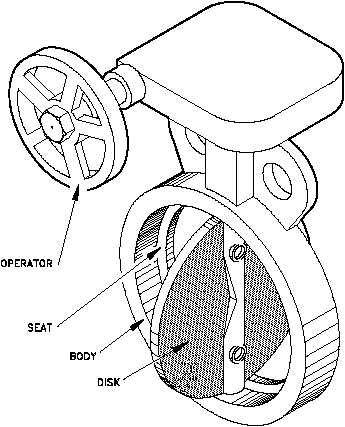

Figure 19 Typical Butterfly Valve

Butterfly Valves

A butterfly valve, illustrated in

Figure 19, is a rotary motion

valve that is used to stop,

regulate, and start fluid flow.

Butterfly valves are easily and

quickly operated because a 90o

rotation of the handle moves the

disk from a fully closed to fully

opened position. Larger butterfly

valves are actuated by handwheels

connected to the stem through

gears that provide mechanical

advantage at the expense of speed.

Butterfly valves possess many

advantages over gate, globe, plug,

and ball valves, especially for

large valve applications. Savings

in weight, space, and cost are the

most obvious advantages.

The

maintenance costs are usually low

because there are a minimal

number of moving parts and there

are no pockets to trap fluids.

Rev. 0

ME-04

Page 31