Valves

DOE-HDBK-1018/2-93

TYPES OF VALVES

The controlling diaphragm transmits a downward force that tends to open the auxiliary valve.

The downward force is exerted by the adjusting spring, which is controlled by the adjusting

screw. Reduced pressure from the main valve outlet is bled back to a chamber beneath the

diaphragm to counteract the downward force of the adjusting spring. The position of the

auxiliary valve, and ultimately the position of the main valve, is determined by the position of

the diaphragm. The position of the diaphragm is determined by the strength of the opposing

forces of the downward force of the adjusting spring versus the upward force of the outlet

reduced pressure. Other reducing valves work on the same basic principle, but may use gas,

pneumatic, or hydraulic controls in place of the adjusting spring and screw.

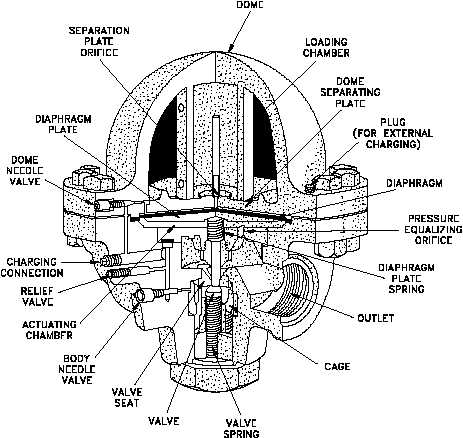

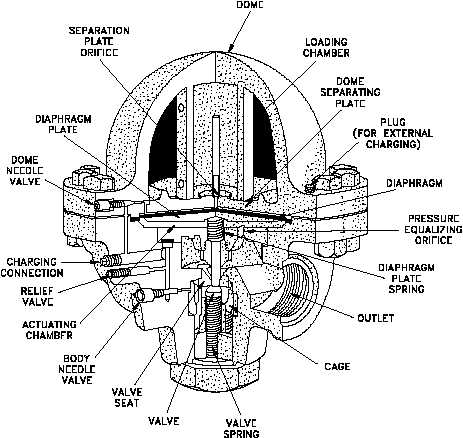

Non-variable reducing valves, illustrated in Figure 17, replace the adjusting spring and screw

with a pre-pressurized dome over the diaphragm. The valve stem is connected either directly

or indirectly to the diaphragm. The valve spring below the diaphragm keeps the valve closed.

As in the variable valve, reduced pressure is bled through an orifice to beneath the diaphragm

to open the valve. Valve position is determined by the strength of the opposing forces of the

downward force of the pre-pressurized dome versus the upward force of the outlet-reduced

pressure.

Figure 17 Non-Variable Reducing Valve

Rev. 0

ME-04

Page 29