TYPES OF VALVES

DOE-HDBK-1018/2-93

Valves

Non-variable reducing valves eliminate the need for the intermediate auxiliary valve found in

variable reducing valves by having the opposing forces react directly on the diaphragm.

Therefore, non-variable reducing valves are more responsive to large pressure variations and are

less susceptible to failure than are variable reducing valves.

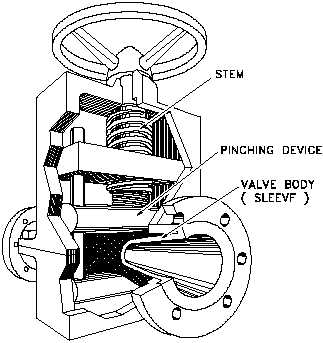

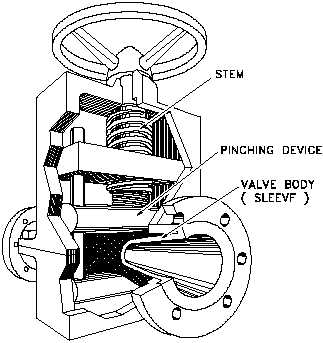

Pinch Valves

The relatively inexpensive pinch valve,

Figure 18 Pinch Valves

illustrated in Figure 18, is the simplest

in any valve design. It is simply an

industrial version of the pinch cock

used in the laboratory to control the

flow of fluids through rubber tubing.

Pinch valves are suitable for on-off

and throttling services. However, the

effective throttling range is usually

between 10% and 95% of the rated

flow capacity.

Pinch valves are ideally suited for the

handling of slurries, liquids with large

amounts of suspended solids, and

systems

that

convey

solids

pneumatically. Because the operating

mechanism is completely isolated from

the fluid, these valves also find

application where corrosion or metal

contamination of the fluid might be a

problem.

The pinch control valve consists of a sleeve molded of rubber or other synthetic material and

a pinching mechanism. All of the operating portions are completely external to the valve. The

molded sleeve is referred to as the valve body.

Pinch valve bodies are manufactured of natural and synthetic rubbers and plastics which have

good abrasion resistance properties. These properties permit little damage to the valve sleeve,

thereby providing virtually unimpeded flow. Sleeves are available with either extended hubs and

clamps designed to slip over a pipe end, or with a flanged end having standard dimensions.

ME-04

Rev.0

Page 30