VALVE ACTUATORS

DOE-HDBK-1018/2-93

Valves

VALVE ACTUATORS

Some type of actuator is necessary to allow for the positioning of a valve.

Actuators vary from simple manual handwheels to relatively complex electrical

and hydraulic manipulators.

EO 1.6

DESCRIBE the construction and principle of operation for the

following types of valve actuators:

a.

Manual

b.

Electric motor

c.

Pneumatic

d.

Hydraulic

e.

Solenoid

Introduction

Valve actuators are selected based upon a number of factors including torque necessary to operate

the valve and the need for automatic actuation. Types of actuators include manual handwheel,

manual lever, electrical motor, pneumatic, solenoid, hydraulic piston, and self-actuated. All

actuators except manual handwheel and lever are adaptable to automatic actuation.

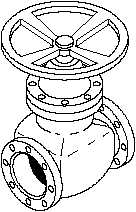

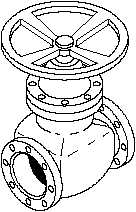

Manual, Fixed, and Hammer Actuators

Manual actuators are capable of

Figure 30 Fixed Handwheel

placing the valve in any position but

do not permit automatic operation.

The most common type mechanical

actuator is the handwheel.

This

type includes handwheels fixed to

the stem, hammer handwheels, and

handwheels connected to the stem

through gears.

Handwheels Fixed to Stem

As

illustrated

in

Figure

30,

handwheels fixed to the stem

provide

only

the

mechanical

advantage of the wheel.

When

these valves are exposed to high operating temperatures, valve binding makes operation difficult.

ME-04

Rev. 0

Page 44