Corrosion

DOE-HDBK-1015/1-93

SPECIALIZED CORROSION

Rev. 0

CH-02

Page 33

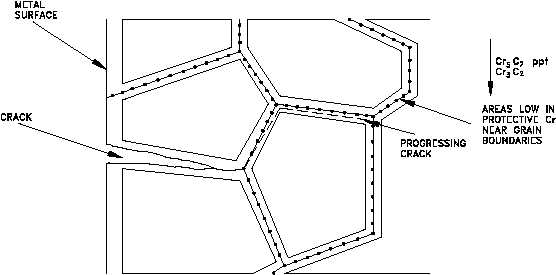

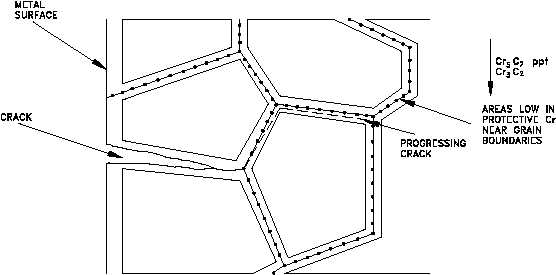

Figure 14 Intergranular Corrosion Cracking

Figure 14 illustrates intergranular stress corrosion cracking. The pressure of a tensile

stress opens up intergranular cracks and accelerates further corrosion. Chloride stress

corrosion is a particularly significant problem in the operation of nuclear facilities

because of the wide use of austenitic stainless steel, and the inherent presence of high

tensile stresses associated with pressurization. Chloride stress corrosion cracks have

been known to propagate in austenitic stainless steel at stresses of about one-fifth yield

strength with chloride concentrations of less than 50 ppm. Yield strength is discussed

in detail in the Material Science Handbook.

Tests show that the 18-8 stainless steels are susceptible to chloride stress attack when

both the chloride ion concentration and dissolved oxygen concentration are above certain

values. The region of susceptibility for austenitic stainless steel is illustrated in Figure

15. Note that when dissolved oxygen is present at about 1 ppm, chloride stress

corrosion cracking can be initiated at chloride ion concentrations near 1 ppm. However,

when the concentration of dissolved oxygen is very low, susceptibility to chloride stress

corrosion cracking is reduced.

High temperature tends to decrease the time required for chloride-induced cracking to

occur, but there appears to be no practical temperature limit below which cracking will

not occur, given sufficient time and severe conditions. The curve in Figure 15 is valid for

temperatures in the range 470?F to 500?F.