STRESS-STRAIN RELATIONSHIP

DOE-HDBK-1017/1-93

Properties of Metals

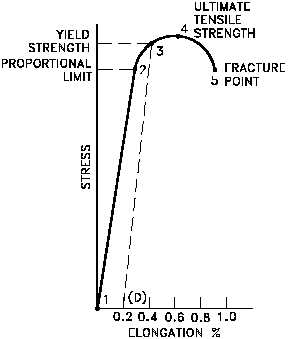

The area between Points 1 and 2 is called the elastic region. If stress is removed,

the material will return to its original length.

Point 2 is the proportional limit (PL) or elastic limit, and Point 3 is the yield

strength (YS) or yield point.

The area between Points 2 and 5 is known as the plastic region because the

material will not return to its original length.

Point 4 is the point of ultimate strength and Point 5 is the fracture point at which

failure of the material occurs.

Figure 3 is a stress-strain curve typical of a

Figure 4 Typical Brittle Material Stress-Strain Curve

ductile material where the strength is small,

and the plastic region is great. The material

will bear more strain (deformation) before

fracture.

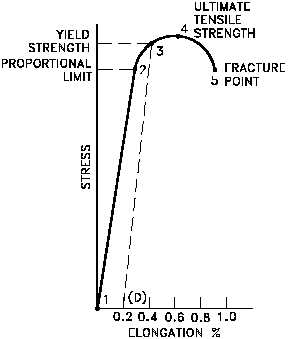

Figure 4 is a stress-strain curve typical of a

brittle material where the plastic region is

small and the strength of the material is high.

The tensile test supplies three descriptive facts

about a material. These are the stress at

which observable plastic deformation or

"yielding" begins; the ultimate tensile strength

or maximum intensity of load that can be

carried in tension; and the percent elongation

or strain (the amount the material will stretch)

and the accompanying percent reduction of

the cross-sectional area caused by stretching.

The rupture or fracture point can also be

determined.

MS-02

Page 18

Rev. 0