Pumps

DOE-HDBK-1018/1-93

POSITIVE DISPLACEMENT PUMPS

With the large number of teeth usually employed on the gears, the discharge is relatively

smooth and continuous, with small quantities of liquid being delivered to the discharge line

in rapid succession. If designed with fewer teeth, the space between the teeth is greater and

the capacity increases for a given speed; however, the tendency toward a pulsating

discharge increases. In all simple gear pumps, power is applied to the shaft of one of the

gears, which transmits power to the driven gear through their meshing teeth.

There are no valves in the gear pump to cause friction losses as in the reciprocating pump.

The high impeller velocities, with resultant friction losses, are not required as in the

centrifugal pump. Therefore, the gear pump is well suited for handling viscous fluids such

as fuel and lubricating oils.

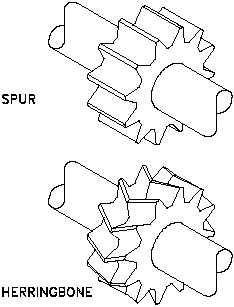

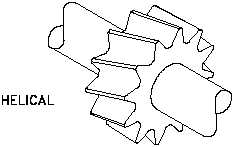

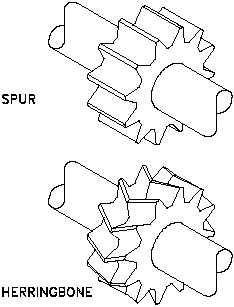

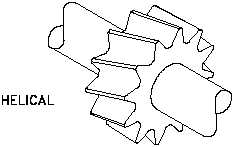

Other Gear Pumps

There are two types of gears used in gear pumps

Figure 15 Types of Gears Used In Pumps

in addition to the simple spur gear. One type is

the helical gear. A helix is the curve produced

when a straight line moves up or down the

surface of a cylinder. The other type is the

herringbone gear.

A herringbone gear is

composed of two helixes spiraling in different

directions from the center of the gear. Spur,

helical, and herringbone gears are shown in

Figure 15.

The helical gear pump has advantages over the

simple spur gear. In a spur gear, the entire

length of the gear tooth engages at the same

time. In a helical gear, the point of engagement

moves along the length of the gear tooth as the

gear rotates. This makes the helical gear operate

with a steadier discharge pressure and fewer

pulsations than a spur gear pump.

The herringbone gear pump is also a

modification of the simple gear pump.

Its

principal difference in operation from the simple

spur gear pump is that the pointed center section

of the space between two teeth begins

discharging before the divergent outer ends of

the preceding space complete discharging. This

overlapping tends to provide a steadier discharge

pressure.

The power transmission from the

driving to the driven gear is also smoother and

quieter.

Rev. 0

ME-03

Page 23