POSITIVE DISPLACEMENT PUMPS

DOE-HDBK-1018/1-93

Pumps

Rotary Pumps

Rotary pumps operate on the principle that a rotating vane, screw, or gear traps the liquid in the

suction side of the pump casing and forces it to the discharge side of the casing. These pumps

are essentially self-priming due to their capability of removing air from suction lines and

producing a high suction lift. In pumps designed for systems requiring high suction lift and self-

priming features, it is essential that all clearances between rotating parts, and between rotating

and stationary parts, be kept to a minimum in order to reduce slippage. Slippage is leakage of

fluid from the discharge of the pump back to its suction.

Due to the close clearances in rotary pumps, it is necessary to operate these pumps at relatively

low speed in order to secure reliable operation and maintain pump capacity over an extended

period of time. Otherwise, the erosive action due to the high velocities of the liquid passing

through the narrow clearance spaces would soon cause excessive wear and increased clearances,

resulting in slippage.

There are many types of positive displacement rotary pumps, and they are normally grouped into

three basic categories that include gear pumps, screw pumps, and moving vane pumps.

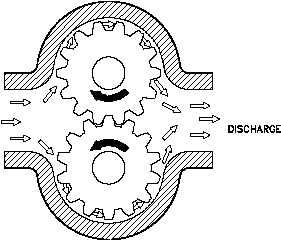

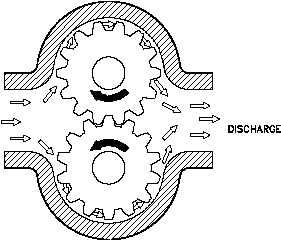

Simple Gear Pump

There are several variations of

Figure 14 Simple Gear Pump

gear pumps. The simple gear

pump

shown

in

Figure 14

consists of two spur gears

meshing together and revolving in

opposite directions within a

casing. Only a few thousandths

of an inch clearance exists

between the case and the gear

faces and teeth extremities. Any

liquid that fills the space bounded

by two successive gear teeth and

the case must follow along with

the teeth as they revolve. When

the gear teeth mesh with the teeth

of the other gear, the space

between the teeth is reduced, and

the entrapped liquid is forced out

the pump discharge pipe. As the

gears revolve and the teeth disengage, the space again opens on the suction side of the

pump, trapping new quantities of liquid and carrying it around the pump case to the

discharge. As liquid is carried away from the suction side, a lower pressure is created,

which draws liquid in through the suction line.

ME-03

Rev. 0

Page 22