Miscellaneous Mechanical Components

DOE-HDBK-1018/2-93

FILTERS AND STRAINERS

Deep-bed filters, like precoat filters, are cleaned by backwashing. Water is pumped through the

distribution piping near the top of the filter. The flow rate of the water is kept high enough to

lift the granulated charcoal or anthracite up into the free space. The water washes away the

deposits that have accumulated. When the backwash cycle is completed, the flow is stopped, and

the granules settle back down into the filter bed. The filter can then be put back into service.

Metal-Edged Filters

Metal-edged filters are used in the lubrication (oil) systems of many auxiliary units. A metal-

edged filter consists of a series of metal plates or disks. Turning a handle moves the plates or

disks across each other in a manner that removes any particles that have collected on the metal

surfaces. Some metal-edged type filters have magnets to aid in removing fine particles of

magnetic materials.

Strainers

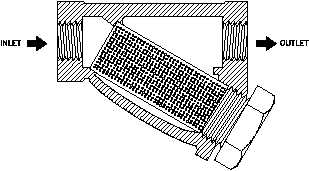

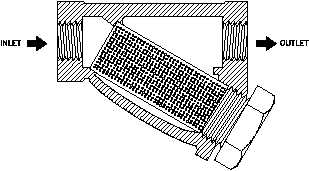

Strainers are fitted in many piping lines to prevent the passage of grit, scale, dirt, and other

foreign matter, which could obstruct pump suction valves, throttle valves, or other machinery

parts. One of the simplest and most common types of strainers found in piping systems is the

Y-strainer, which is illustrated in Figure 23.

Figure 23 Y-strainer

Figure 24 illustrates three additional common types of strainers. Part A shows a typical sump

pump suction bucket strainer located in the sump pump suction line between the suction manifold

and the pump. Any debris that enters the piping is collected in the strainer basket. The basket

can be removed for cleaning by loosening the strongback screws, removing the cover, and lifting

the basket out by its handle.

Part B of Figure 24 shows a duplex oil strainer commonly used in fuel oil and lubricating oil

lines, where it is essential to maintain an uninterrupted flow of oil. The flow may be diverted

from one basket to the other, while one is being cleaned.

Rev. 0

ME-05

Page 45