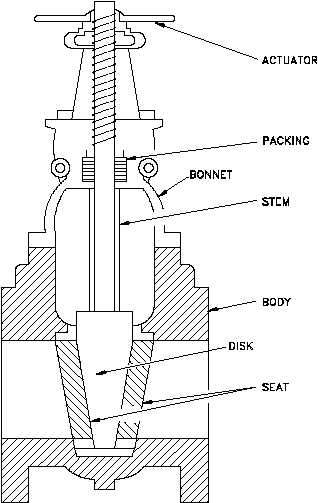

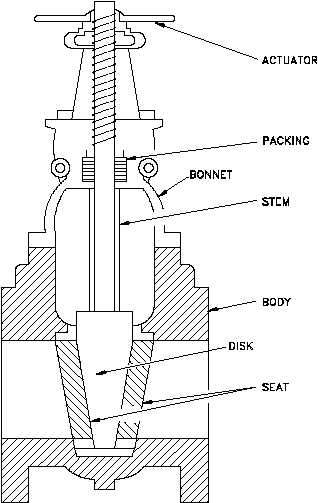

VALVE FUNCTIONS AND BASIC PARTS

DOE-HDBK-1018/2-93

Valves

Valve Body

The body, sometimes called the shell, is the primary pressure boundary of a valve. It serves as

the principal element of a valve assembly because it is the framework that holds everything

together.

The body, the first pressure boundary of a valve, resists fluid pressure loads from connecting

piping. It receives inlet and outlet piping through threaded, bolted, or welded joints.

Valve bodies are cast or forged into a

Figure 1 Basic Parts of a Valve

variety of shapes. Although a sphere

or a cylinder would theoretically be

the most economical shape to resist

fluid pressure when a valve is open,

there are many other considerations.

For example, many valves require a

partition across the valve body to

support the seat opening, which is the

throttling orifice.

With the valve

closed, loading on the body is

difficult to determine. The valve end

connections also distort loads on a

simple sphere and more complicated

shapes.

Ease of manufacture,

assembly, and costs are additional

important considerations. Hence, the

basic form of a valve body typically

is not spherical, but ranges from

simple block shapes to highly

complex shapes in which the bonnet,

a removable piece to make assembly

possible, forms part of the pressure-

resisting body.

Narrowing of the fluid passage

(venturi effect) is also a common

method for reducing the overall size

and cost of a valve.

In other

instances, large ends are added to the

valve for connection into a larger

line.

ME-04

Rev. 0

Page 2