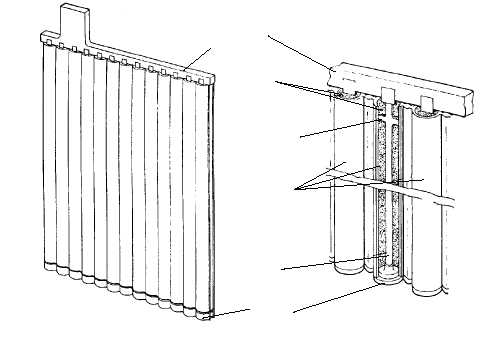

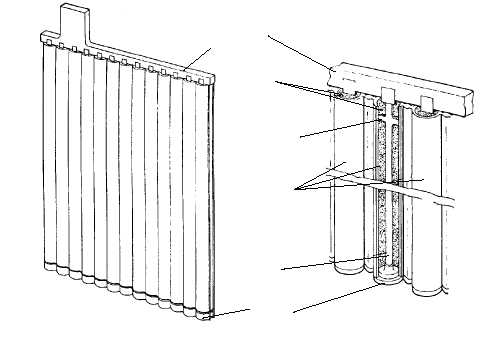

Connector

bus

Active

material

Centering

projections

Porous

separators

Axial

lead

current

collector

End cap

OPERATION AND CONSTRUCTION

DOE-HDBK-1084-95

Lead-Acid Storage Batteries

Batteries

Page 16

Rev. 0

Figure 6. Typical construction of a tubular plate.

The two most common alloys used today to harden the grid are antimony and calcium.

Batteries with these types of grids are sometimes called "lead-antimony" and "lead-

calcium" batteries. Tin is added to lead-calcium grids to improve cyclability. The

major differences between batteries with lead-antimony and lead-calcium grids are as

follows:

1.

Lead-antimony batteries can be deep cycled more times than lead-

calcium batteries.

2.

Flooded lead-antimony batteries require more frequent maintenance as

they near end-of-life since they use an increasing amount of water and

require periodic equalization charges.

3.

Lead-calcium batteries have lower self-discharge rates as shown in

Figure 7 and therefore, will draw less current while on float charge than

lead-antimony batteries.

4.

Lead-calcium positive plates may grow in length and width because of

grid oxidation at the grain boundaries. This oxidation is usually caused